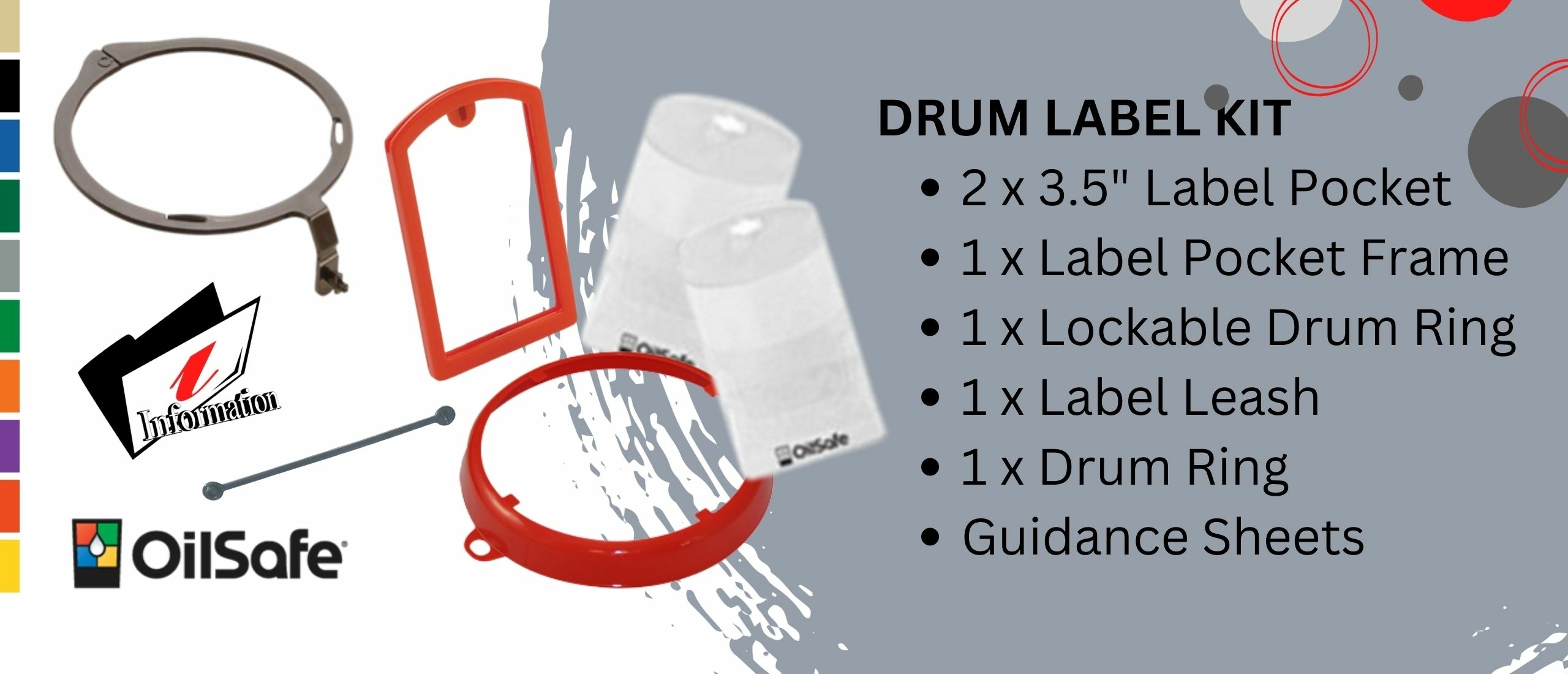

Drum Label Kit

The Drum Label Kit is designed to be used in conjunction with the OilSafe Lid and Drum, which also feature a colour-coding system that matches the labels. This system helps prevent cross-contamination and ensures that the correct lubricant is used in the right place, reducing the risk of equipment damage or failure.

Drum Label Kit available in the 10 OilSafe colours

Using the Drum Label Kit and OilSafe system together provides an effective way to visually identify (10 OilSafe colours) and manage lubricants, improving safety, efficiency, and productivity in industrial settings.

OilSafe drum + lid and some parts of the Drum Label Kit

OilSafe drum + lid and some parts of the Drum Label Kit

Each Kit includes the following components:

- 2 x 3.5" Label Pocket

- 1 x Colour-coded Label Pocket Frame

- 1 x Lockable Drum Ring

- 1 x Label Leash

- 1 x Colour-coded Drum Ring

- Guidance Sheets - Best practice suggestions for common labeling applications*

Available in Oil Safe's 10 standard colours.

Specification

Weight: 72.57 gram

Part #: 207100 - 207109

Features

- Ensures the right lubricant goes into the right machine every time.

- Improves OSHA compliance.

- Is industrial grade, high quality and suitable for outdoor use.

- Accommodates inclusion of MSDS at all steps of the lubrication process.

- Enables consistent identification of bulk storage, container and point of use.

- Is flexible and suitable for multiple work place applications.

- Improves productivity and efficiency.

- Increases bottom line savings.

Labeling applications*

Labeling applications are used in various industries for different purposes, such as safety, compliance, or organization. Here are some suggestions for common labeling applications:

- Hazard warnings: Labels can be used to identify hazardous materials or products and provide safety warnings to workers and others who handle or come into contact with them.

- Container identification: Labels can be used to identify different types of containers, such as drums or tanks, and the products they contain. This helps prevent cross-contamination and ensures that the right product is used in the right place.

- Product identification: Labels can be used to identify products and provide information such as product name, grade, and usage instructions. This can be useful for maintaining proper inventory and tracking product usage.

- Asset tracking: Labels can be used to identify and track equipment or assets, such as tools or machinery. This helps with maintenance, inventory control, and theft prevention.

- Calibration tracking: Labels can be used to track the calibration history of equipment or instruments, ensuring that they are regularly checked and adjusted to maintain accuracy.

- Compliance labeling: Labels can be used to comply with regulations and standards, such as OSHA or GHS requirements for safety labeling of hazardous materials.

- Organization: Labels can be used to organize and categorize items, such as supplies or inventory. This helps with inventory control and streamlining processes.

Overall, labeling applications are versatile and can be used in various industries and settings to improve safety, efficiency, and organization. The specific labeling needs will depend on the industry and the purpose of the labeling, but the above suggestions are common applications that may be applicable to many industries.