>35

500+

1000+

“Pillars set in stone”, features the poem, written by Ian Knight. It describes the foundation of Enluse back in 2002.

The BOP20 and BOP60 family

The recently improved BOP: a portable, 18-volt battery-operated oil pump designed to boost workshop efficiency while alleviating the fatigue often linked with manual pump operation. The Pump Stem stands as a groundbreaking innovation, enabling a single stem to proficiently handle various fluid types. The redesigned Pump Stem eliminates the requirement for specific stems per fluid, delivering a versatile solution that suits a wide array of applications effortlessly.

Latest Blogs

Find more info on all

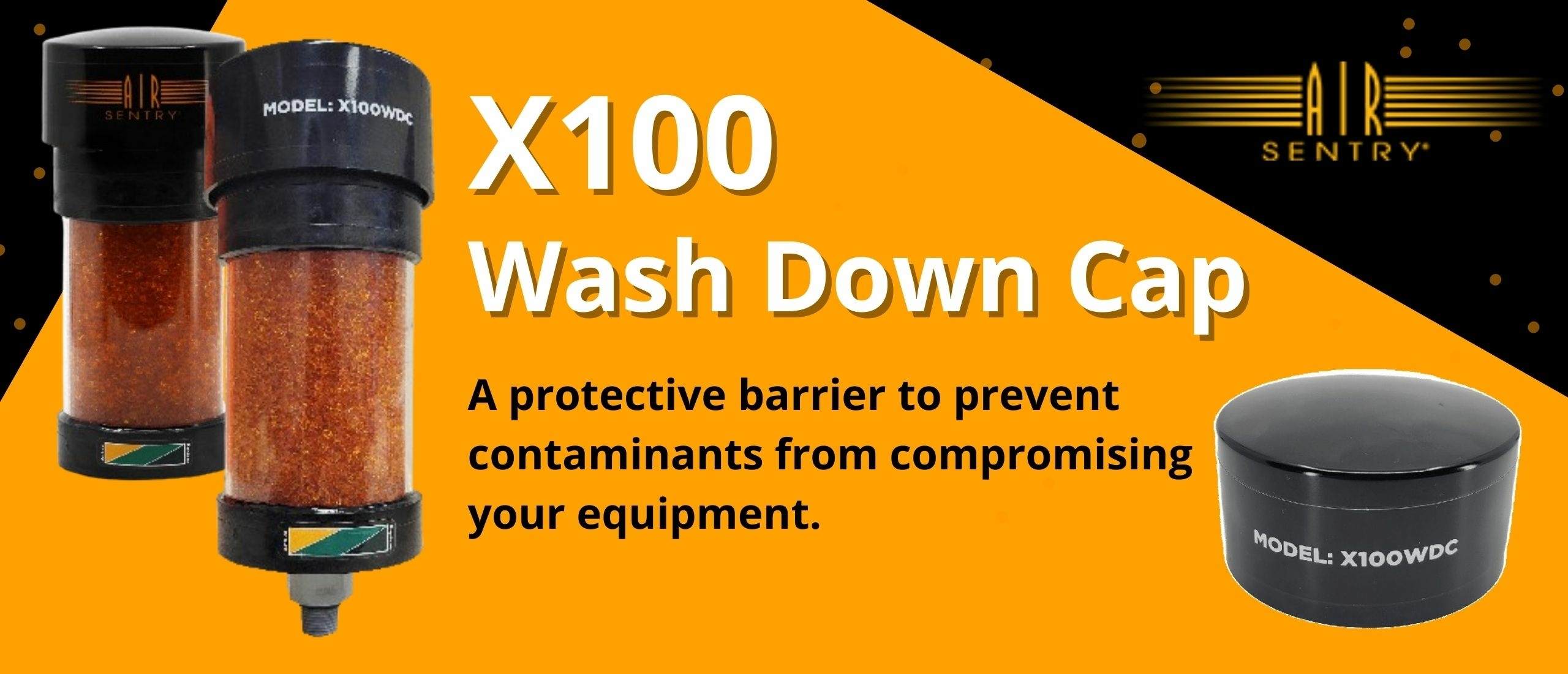

Lubrication Reliability Products

Discover how to safeguard your machinery!

About Enluse

Enluse B.V. is a specialised B2B industrial supply company in the field of lubrication management, serving a network of dealers / agents all over Europe. We are a small team of decentralised people located in The Netherlands, Belgium, Germany and UK . The company is undergoing a B2B development / reorganisation, where webshop and online sales will be the dominant sales channel.